Once the dynamics of the procurement organization have been defined, managers can move on to the third step of developing a procurement strategy – establishing a procurement inventory strategy. The objective of this step is to ensure the timely and cost-effective acquisition of required inventories to support the company’s operations.

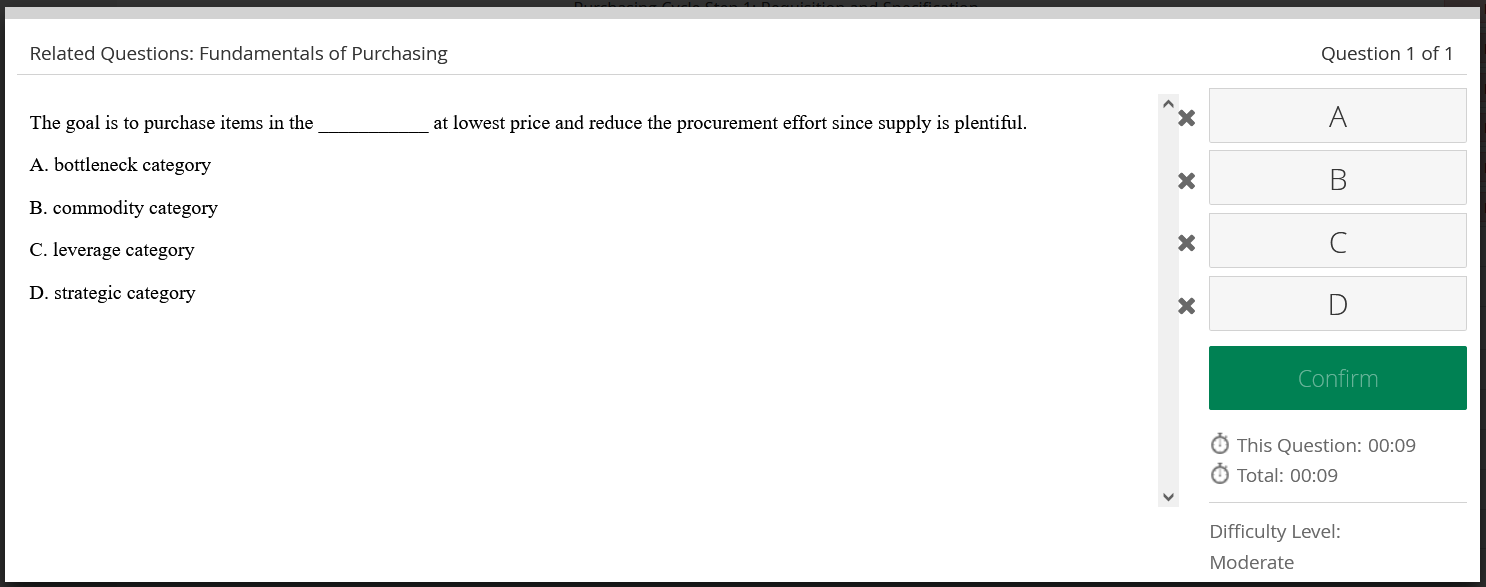

Spend Analysis

Firstly, it is crucial to conduct a thorough analysis of the company’s expenses. This entails scrutinizing all the goods and services acquired by the firm to establish the precise spending levels and supplier diversity. The analysis should document the expenditure incurred on particular products and categories, outlining the items purchased, the procurement methods used, the suppliers involved, and their location.

New Product Development Requirements

This task involves identifying the goods and services needed for new product development. The aim is to determine the costs, amount of effort required by procurement staff, and necessary technologies. These costs will be included in the procurement budget.

Financial Budgets

One of the main tasks is to create a budget for procuring inventory. To do this, we analyze historical spending data, new product development, and plans from long-range MRP planning, among other factors.

Make/Buy Decision

This activity involves deciding whether certain items should be produced in-house or outsourced to a supplier.

Materials and Services Classification

This activity involves ranking products and services based on their significance to the organization. The assessment considers two crucial values: the value of the product or service to the customer and the level of supply risk associated with it.

Classification involves separating purchased products and services into four quadrants:

Make these below into 4 definitions

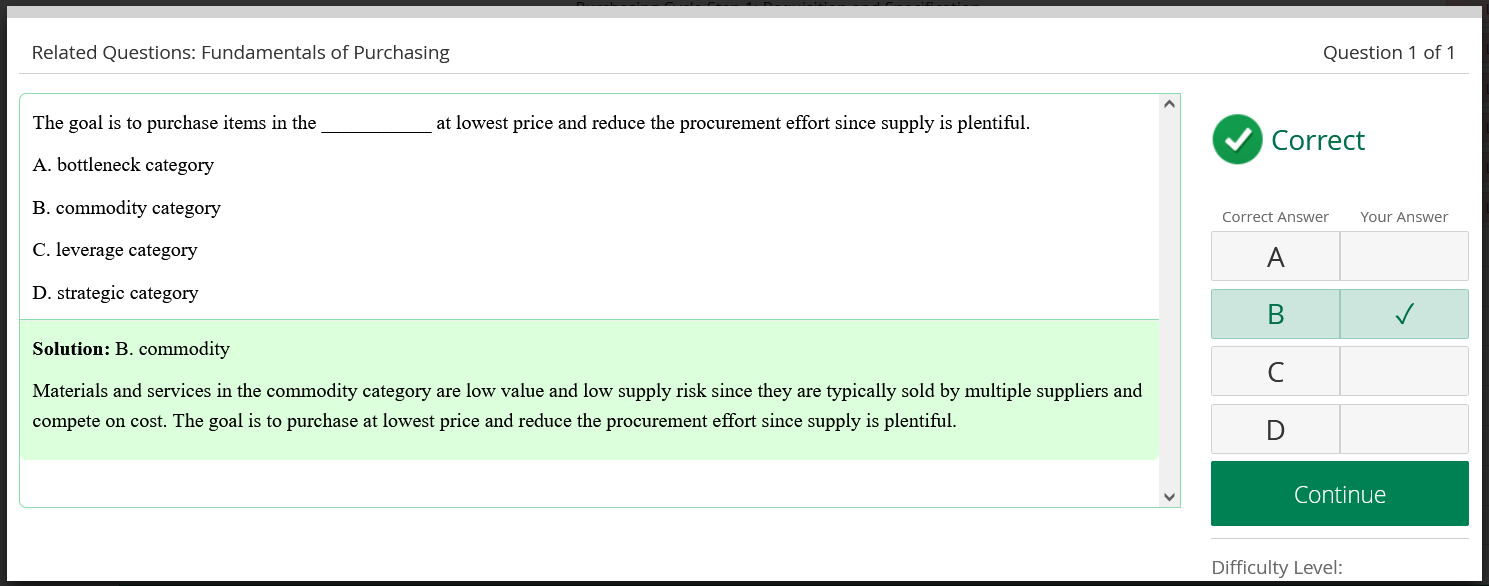

- Commodity: Materials and services in the commodity category are low value and low supply risk since they are typically sold by multiple suppliers and compete on cost. The goal is to purchase at lowest price and reduce the procurement effort since supply is plentiful.

Commodity is “[a]n item that is traded in commerce. The terms usually implied an undifferentiated product competing primarily on price and availability.” (APICS Dictionary, 16th edition).

- Bottleneck: Materials in the bottleneck category are low in value but high in supply risk. Frequently the high risk of supply is based on limited number of suppliers offering the product. The goal is to ensure supply continuity and consider long term agreements if possible.

Bottleneck – “A facility, function, department, or resource whose capacity is less than the demand placed upon it. For example, a bottleneck machine or work center exists where jobs are processed at a slower rate than they are demanded. Syn: bottleneck operation” (APICS Dictionary, 16th edition).

- Leverage: Materials and services in the leverage are high value and low supply risk. There are multiple suppliers in this category, as there are in the commodity category. The goal is to leverage purchases to optimize costs. This can be accomplished by consolidating volume with selected limited number of suppliers.

- Strategic: Materials and services in the strategic category are high value and high supply risk. There are limited suppliers and materials and services are critical to the organization. The goal is to have a strong relationship with the supplier for continued supply and potentially collaborate on lowest total cost.