After the first two steps in the purchase order flow process, the third step involves generating a purchase order (PO) status and performance report. This report is critical for two main reasons. Firstly, it allows the purchasing department to determine the status and cost of each PO on an operational level. Secondly, on a strategic level, it enables the purchasing department to measure its impact on the overall competitiveness of the business and adherence to corporate budgets.

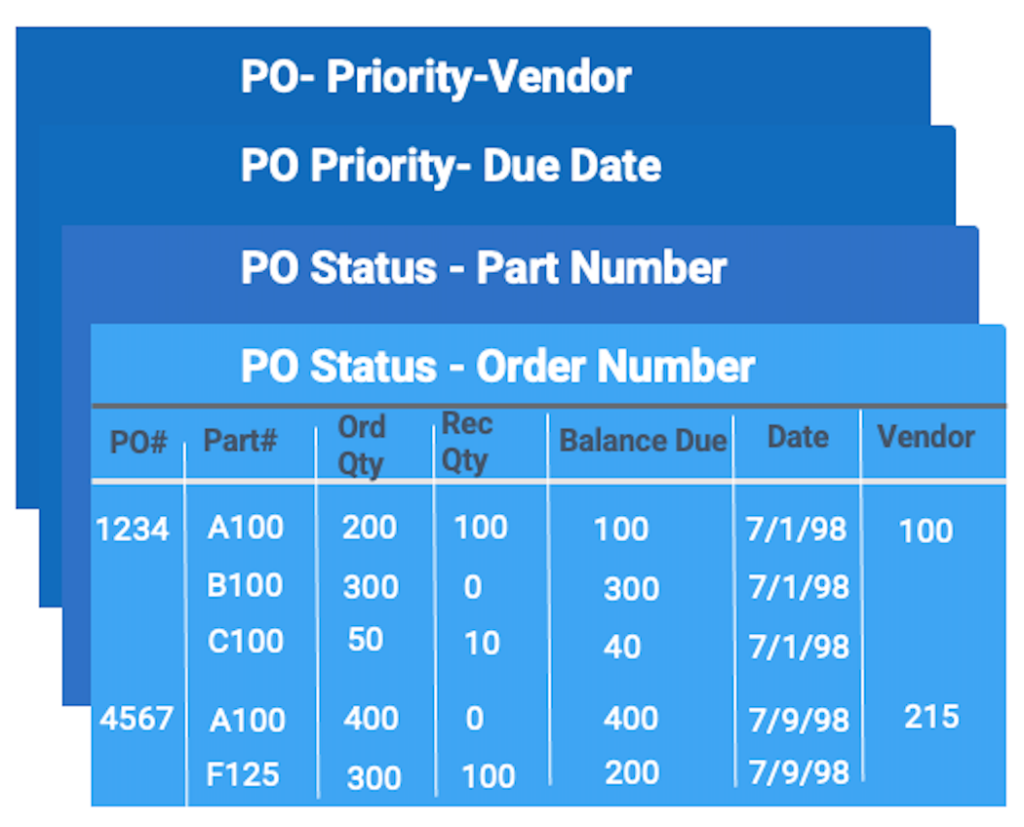

PO Status Reports

These reports display the current statuses of open requisitions and purchase orders. They can be sorted based on various criteria, such as supplier, due date, product, or order number. All reports contain important details, including the PO number, scheduled due date, ordered items and quantities, current receiving information, and open balance.

PO Priority Reports

Purchase planners use priority reports as a follow-up tool to keep track of their orders. These reports show which purchase orders (POs) are not synchronized with the demand quantities and due dates. By using these reports, planners can identify any potential material shortages and avoid costly expediting fees. Additionally, these reports help planners maintain the schedule of PO priorities.

Strategic Performance Reporting

There are two main areas of strategic PO reporting:

1. Reporting on a monthly or bi-monthly basis is essential to track the impact of purchasing on enterprise operations controls and plan for the future. The report should include a summary of the general business climate, major product price changes, current lead times for major materials and suppliers, and a list of material shortages. The report should also outline purchasing’s strategy for handling each shortage.

2. A monthly or quarterly report should summarize the state of the purchasing function and efforts to increase the company’s profitability and competitive advantage. The report should cover quality, reliability, supplier, and cost improvements. It should also include operational statistics such as operating cost, dollar commitments against budget, and number of purchase orders issued. Finally, the report should briefly describe departmental efforts for continuous quality improvements and elimination of wastes, and provide a statement of future procurement projects and administrative activities.