One of the tools available for organizations to reference or measure their own performance against is benchmarking. Benchmarking is an effective way to guide procurement and supply chain improvement, raising awareness among management of best-in-class business practices for a particular process or industry. It provides the following benefits:

- Identification of standards of excellence that can lead to performance improvement

- Elimination of barriers to change by allowing corporations to view what is happening externally

- Minimization of cost of trial and error by trying techniques that have worked well for other companies

- Development of relationships with other firms, including customers and suppliers

Methods for Benchmarking

Several methods exist for benchmarking, depending on what type of measurement is needed.

- Operational benchmarking focuses on functional activities in order to improve performance. This can be performed against best-in-class organizations, or accepted world-class processes. It can be done two ways: ◦ External benchmarking is used to look for best practices on products, services, or processes. This type of benchmarking can be done within a particular industry or a sector, whether it be related or non-related to the organization’s industry. ◦ Internal benchmarking can be used to compare different versions of purchased products items or services within an organization, such as to determine which suppliers, items or processes are the most sustainable

- Competitive benchmarking is benchmarking a product or service against competitors (APICS Dictionary, 16th edition). It provides information on how to respond to competition and allows companies to get an evaluation of how they are performing.

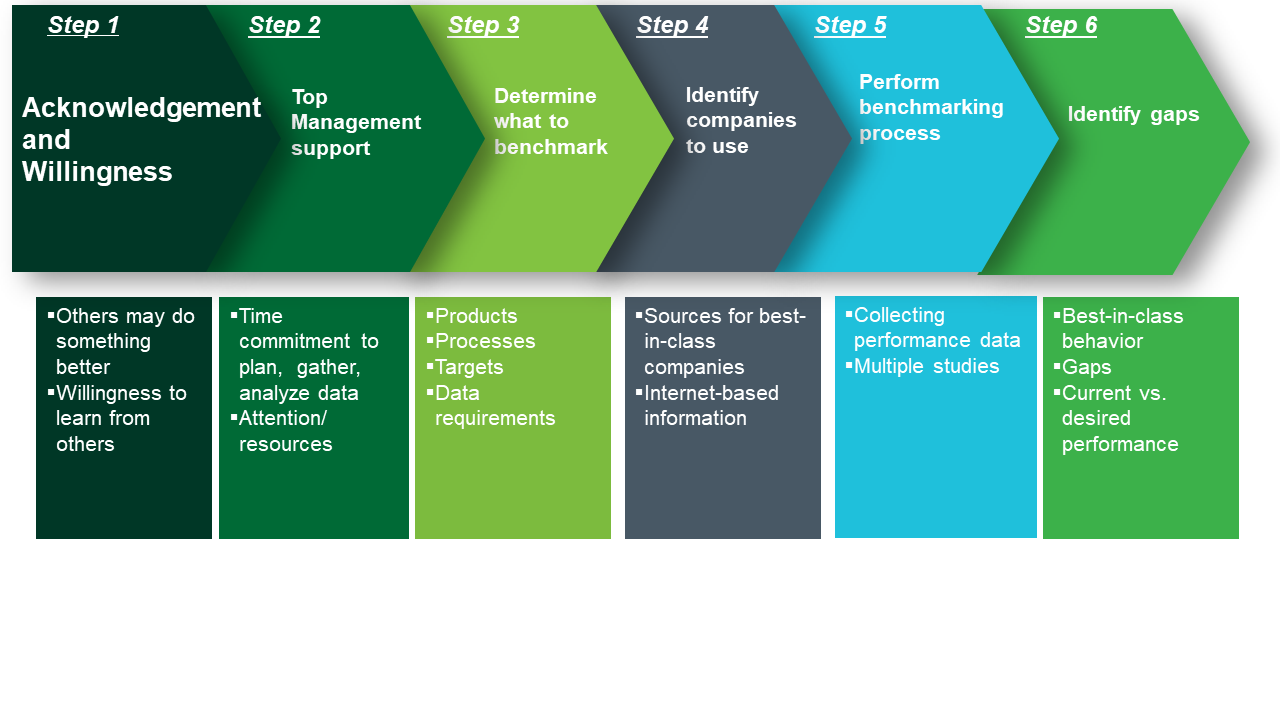

Benchmarking Steps

The following steps are used to initiate a benchmarking exercise:

Step 1: Acknowledge that another company may do something better, and have a willingness to learn from others.

Step 2: Top management support is required in order to get the commitment for the time necessary to plan, gather data and analyze. Oftentimes benchmarking does not get the attention it needs due to a lack of time and resources.

Step 3: Determine which products or processes will be benchmarked, as well as targets, and data requirements for each.

Step 4: Identify companies that will be used for benchmarking in each area. Many sources exist for determining which companies are considered best-in-class, including business library resources, the internet, trade journals, consultants, conferences, suppliers, and research firms. Two examples of internet-based firms that provide benchmarking information are: Caps Research and Benchmarking Success

Step 5: Perform the benchmarking process by collecting performance data for each process or product. Some companies make the mistake of limiting the benchmarking results to only one study, which can lead to a very narrow perspective.

Step 6: After determining best-in-class behavior from the benchmarked organization, identify gaps between the organization’s current performance and desired performance. Many companies begin by benchmarking themselves against the Supply Chain Operations Reference (SCOR) model in areas such as delivery performance, fill rates, perfect order fulfillment, cash-to-cash cycle time, inventory turns, etc.