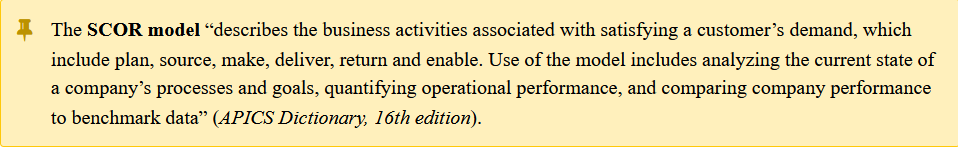

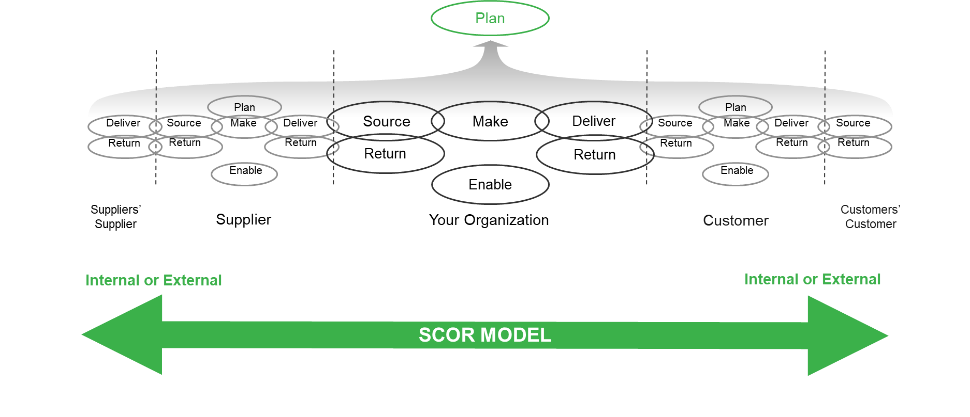

Some of the most well-known and most detailed performance metrics for supply chain are encompassed in the Supply Chain Operations Reference (SCOR) model.

Organizations use the standard definitions and data requirements within the SCOR model to evaluate their supply chains and link tactical level metrics back to strategic goals and measurements.

SCOR Metrics

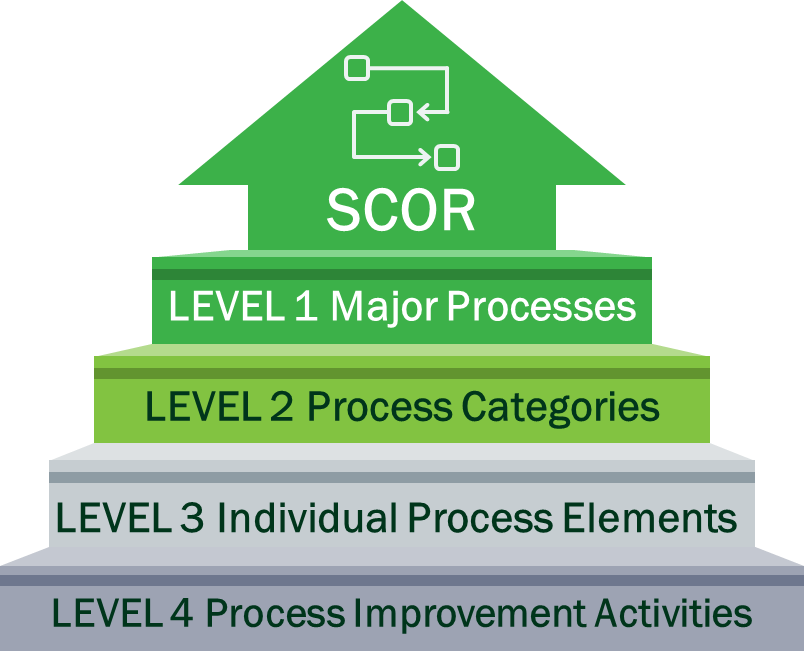

SCOR metrics “measure the ability of processes to achieve the strategic objectives associated with performance attributes” (APICS Dictionary, 16th edition). They are defined in three levels, with an additional level for tools.

Level 1: Measures the overall health of the supply chain, and provide key performance indicators for strategic directions and major processes.

Level 2: Uses process categories to define operations strategy and set process capabilities.

Level 3: Uses individual process elements to focus on inputs/outputs, skills, performance, best practices and capabilities.

Level 4: Defines tools and activities to be used for improvement.

SCOR Performance Attributes

SCOR categorizes its series of metrics into five performance attributes. Performance attributes are “a classification for metrics used to formulate strategic direction” (APICS Dictionary, 16th edition).

|

Performance Attribute |

Definition |

|

Reliability |

The ability to perform tasks as expected. Reliability focuses on the predictability of the outcome of a process. Typical metrics for the Reliability attribute include delivering a product on time, in the right quantity and at the right quality level. |

|

Responsiveness |

The speed at which tasks are performed and the speed at which a supply chain provides products to the customer. Examples include cycle-time metrics. |

|

Agility |

The ability to respond to external influences and marketplace changes to gain or maintain a competitive advantage. SCOR Agility metrics include adaptability and overall value at risk. |

|

Costs |

The cost of operating the supply chain processes. This includes labor costs, material costs, and management and transportation costs. A typical cost metric is cost of goods sold. |

|

Asset Management |

The ability to efficiently use assets. Asset management strategies in a supply chain include inventory reduction and insourcing rather than outsourcing. Metrics include inventory days of supply and capacity utilization. |

SCOR Practices

SCOR also classifies business processes into nineteen practices to assist businesses in identifying areas of interest. Processes within these are also broken down by standard, best, and emerging practices.

|

Business Process Analysis and Improvement |

Customer Support |

|

Distribution Management |

Information and Data Management |

|

Inventory Management |

Manufacturing and Production |

|

Material Handling |

New Product Introduction |

|

Order Engineering |

Order Management |

|

People Management (Including Training) |

Planning and Forecasting |

|

Product Lifecycle Management |

Purchasing and Procurement |

|

Reverse Logistics |

Risk and Security Management |

|

Sustainable Supply Chain Management |

Transportation Management |

|

Warehousing |

|

Special Applications of SCOR

Some special applications of SCOR include:

- SustainableSCOR, which provides a set of metrics that is closely aligned with the Global Reporting Initiative (GRI) standards to aid organizations in measuring the sustainability aspects of their supply chain.

- SCORmark, which allows members to benchmark performance against selected peer companies, using a benchmarking portal.