Performance measures and metrics should be part of any trading partner relationship within the supply chain. Continuous measurement and evaluation of suppliers is an important element of the management of suppliers and the procurement function.

Supplier measurements can be used in a variety of ways:

- Making sourcing decisions for new and existing products and services

- Identifying suppliers that cannot perform at expected levels so that actions can be taken to bring performance up to the standard, or to find a new supplier

- Determining a supplier’s future purchase volume, including additional contracts, based on their performance ratings

- Identifying suppliers that qualify for preferred status or long-term partnerships due to excellent performance

- Identifying overall areas needing improvement across the supply base

Ways to Measure Suppliers

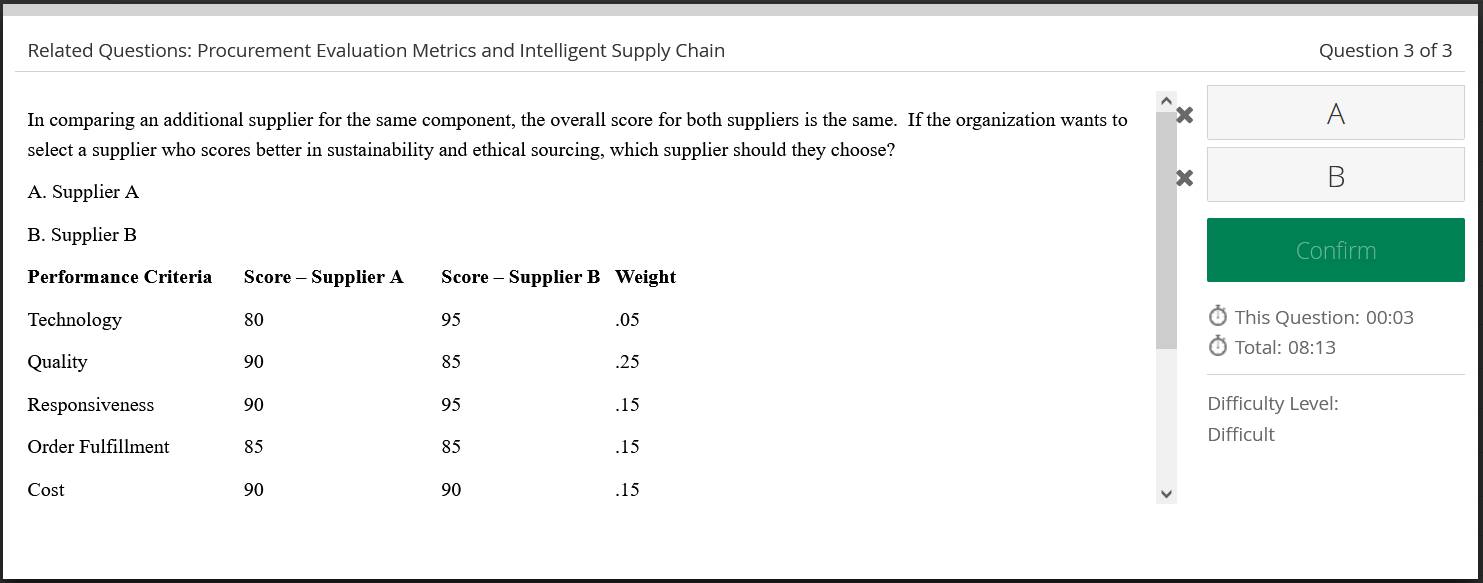

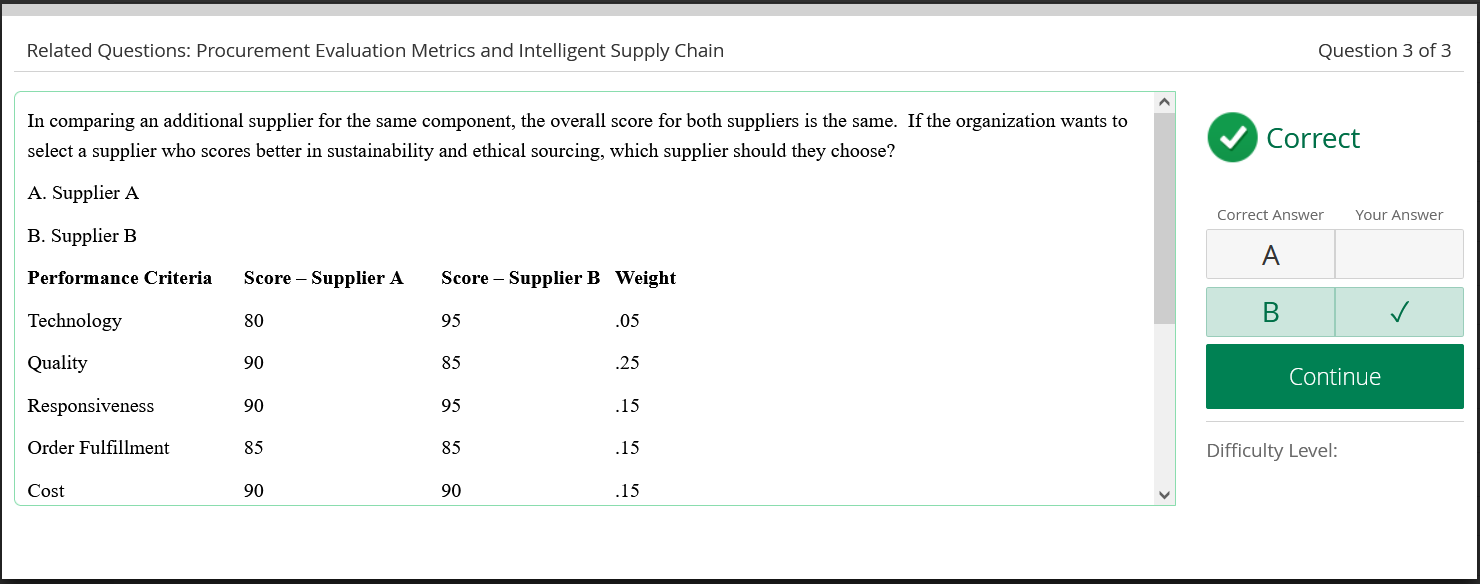

Several methods can be used for evaluating suppliers. To develop the best supplier measurement strategy, it is often beneficial to segment the suppliers by type of product or service, or risk level or spend amount, to determine which types of measurements and data are necessary.Categories. This is a relatively easy and inexpensive method and is also the most subjective. It consists of determining a rating such as excellent, good, fair, or poor to each specific area of performance, e.g., on-time delivery performance or quality. Cost. This method calculates the total cost of doing business with each supplier. It can be used to compare the total cost of ownership (TCO) for each item purchased from each supplier. It can be difficult to do if the financial system cannot capture the data required, or identify the costs incurred when a supplier does not perform as expected.Weighted. This method provides scores across each area of performance, which are weighted based on organizational priorities or types of supplier. Firms decide what performances should be measured, assign a weight to each, and determine minimum standards. The steps for creating a weighted supplier rating are:Step 1: Select the mutually acceptable dimensions of supplier performance.Step 2: Assign weights to each dimension based on relative importance to corporate objectives; weights must sum to 1.Step 3: Collect supplier performance data.Step 4: Evaluate and rate the supplier on each of the dimensions.Step 5: Multiple the dimension rating by the importance weight.

Example of Supplier Rating

|

Dimension |

Rating 1-100(100 is best) |

Weight |

Weighted Rating |

|

Quality |

94 |

0.30 |

28.2 |

|

Cost |

90 |

0.25 |

22.5 |

|

Delivery |

82 |

0.25 |

20.5 |

|

Sustainability |

85 |

0.20 |

17.0 |

|

Overall combined weighted rate |

88.2 |

||

Step 6: If needed, suppliers can be classified based on overall scores. Examples of scoring levels might be:

- Unacceptable: less than 50 – no longer use

- Conditional: between 50 and 70 – work with supplier to improve performance

- Certified: between 70 and 90 – supplier meets intended performance

- Preferred: 90 and above – supplier considered for future business opportunity

Step 7: Perform ongoing supplier evaluation process.

Guidelines of a Supplier Measurement System

In addition to the guidelines previously discussed for implementing a performance measurement system, the following apply when measuring suppliers:

- Goals should be communicated, attainable, measurable, and appropriate to the supplier being measured.

- The program should be developed collaboratively.

- Supplier ratings should be tied to overall service level agreements.

- The type of reporting and frequency that will be used should be defined, as well as the frequency of feedback from the buyer back to the supplier.

- Supplier evaluations should include not only tangible measures such as on-time delivery and quality, but also less-tangible measures, such as honesty, communication and responsiveness.

Many companies elect to have suppliers perform and communicate an evaluation of their own performance as part of the evaluation process, which promotes buy-in of the supplier to the measurement program.